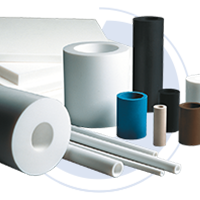

3P company first grew on basic shapes and rapidly offered finished plastic parts for industrial use. The focus on manufacturing also includes assemblies and post-treatments. This guarantees for each customer a dedicated, ready-to-use configuration of 3P’s solutions.

The most significant example is the etching process. While 3P uses many thermal or mechanical treatment and post-treatment to enhance materials properties, the integration of its own etching process by sodium ammonia shows 3P’s commitment in delivering state-of-the-art process.

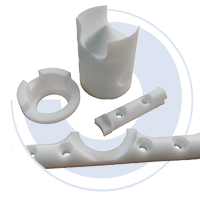

With the need of integrated solutions, 3P has also developed a full range of assembly know-how: assembly of finished parts, machined or injected, but also assembly of tubes, for example with connectors. 3P also offers bonding capabilities, in compliance with its know-how in etching process.

Finishing processes are also available: laser marking, curing, encasing, fastening, painting etc. All these technics allow a tuned offer for demanding industry, from basic shapes to keyturn solutions.

Finally, packaging is also an important part of custom solutions. Some industrial production require specific packaging. For example, custom packing allows faster installation and global profitability. On the contrary, standard conditioning can prove to be easier to handle.