FEP plastics, the best chemical resistance for versatile parts

FEP material is a fluoropolymer commonly used in tubes or injected parts, with high chemical resistance restraint and is found as an injected part or as tube.

FEP plastics offers performance near that of PTFE

FEP, Fluorinated ethylene propylene, is a copolymer of tetrafluoroethylene (the base component of PTFE) and hexafluoropropylene, and as such is part of the fluoropolymer family. The structure is near that of PFA, without oxygen atoms: a CF3 group is bonded on some carbon atoms of the polymer chain. Thus FEP is only based on carbon-carbon and carbon-fluorine bonds, just like PTFE, and is the only fluoropolymer matching PTFE’s chemical resistance. It is resistant to nearly all chemicals, except molten alkali metals, gaseous fluorine, and some complex halogenated compounds.

FEP has a much lower melting point than PTFE, at 260°C, and its recommended maximum operating temperature is 205°C.

FEP is also slightly more rigid than PTFE and offers less flexlife.

One important asset of FEP is its high transparency. FEP is amongst the clearest fluoropolymers. It is therefore commonly used in medical applications requiring UV treatment of fluids.

FEP can be shaped with all kind of processes.

FEP properties

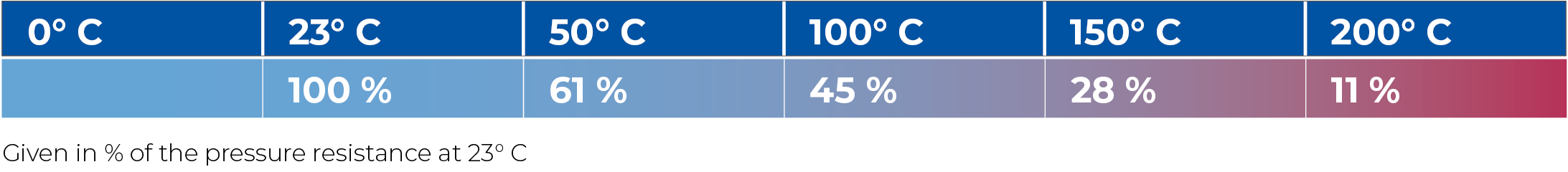

- Good thermal stability

- Operating temperature from -200°C to 205°C

low coefficient of friction

Chemical properties

- Outstanding Corrosion and Chemical resistance,

- Chemically inert, with FDA grades available

- Low permeability to liquids, gases and moisture

- Anti-ageing properties, with UV resistance

Electrical properties

- Excellent dielectric properties

- Low dielectric constant