Solutions for industrial fluids in high performance plastic parts

Fluid Handling systems, mainly Oil & Gas or chemical industries, require parts resistant to harsh environments, with high temperature, high pressure, high wear and corrosion. High performance plastics overcome all constraints met in the most extreme environments. New compounds enable solutions at the forefront of efficiency requested every day, and even tomorrow.

Assets of high performance polymers in oil & gas and chemical industries

For such demands, oil & gas or chemical industry heavily rely on high performance plastics, especially, PTFE, PEEK as well as PFA or PCTFE.

Our products shows optimal properties, such as:

- Excellent resistance in harsh chemical environments (organic and inorganic)

- Exceptional shock, toughness and abrasion resistance (mechanical and thermal)

- Extended product life

- Continuous service temperature from -250° up to 315°C (-420° up to 600°F) depending on material

- Outstanding dimensional stability even under high pressure

- Good flammability rating

3P develops solutions for petrochemical pumps and valves

3P’s solutions are especially assessed in pumps and valves for the petrochemical industry, where its own designed compounds improve longevity and efficiency of equipments. In pumps, feedback of users have shown efficiency gain up to 7%, not to mention the lowered maintenance.

Keyturn solutions are preferred for the best quality and trust in final products. However, semi-finished products can be supplied to answer rapid needs. In this case, a stock of common products can directly machined on site.

The trust of our customers has led 3P to develop its own range of material. Along with standard materials that have proven their efficiency over time, 3P develops proprietary compounds and composites. Inspired by our customers they answer the new needs of the industry: cryogenic temperature, low gas permeability, vibration reduction are some of the challenges we answer daily.

Efficient solutions for fluid handling systems industry

3P solutions can be found in many applications in fluid handling systems: tanks and containers, hoses, pipelines, gas and hydrocarbon pumps, boiler pipes, Archimede screws and other rotating machines.

- Pump

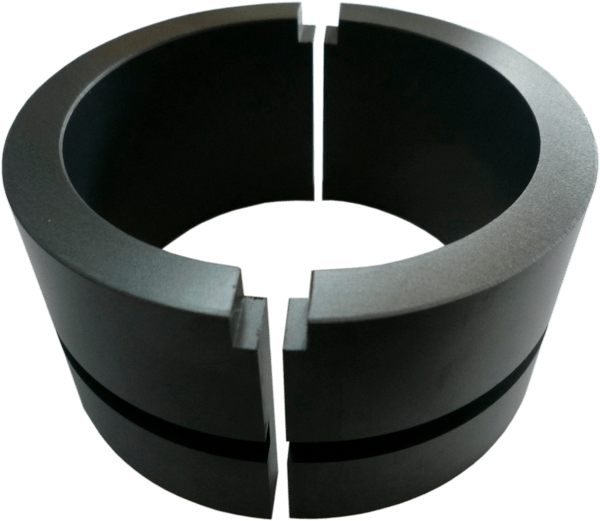

- High wear resistance bearings

- Low clearance bushings for increased efficiency

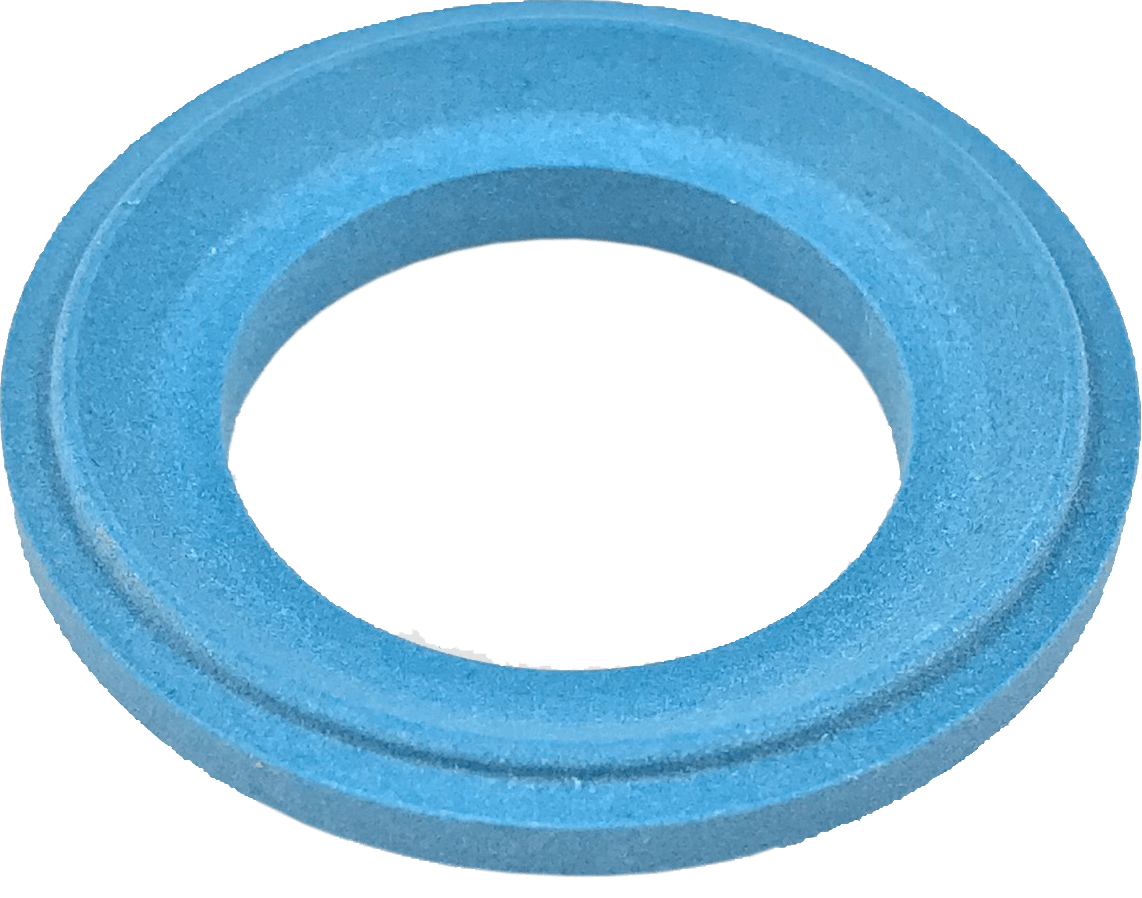

- Large chemical resistance washers

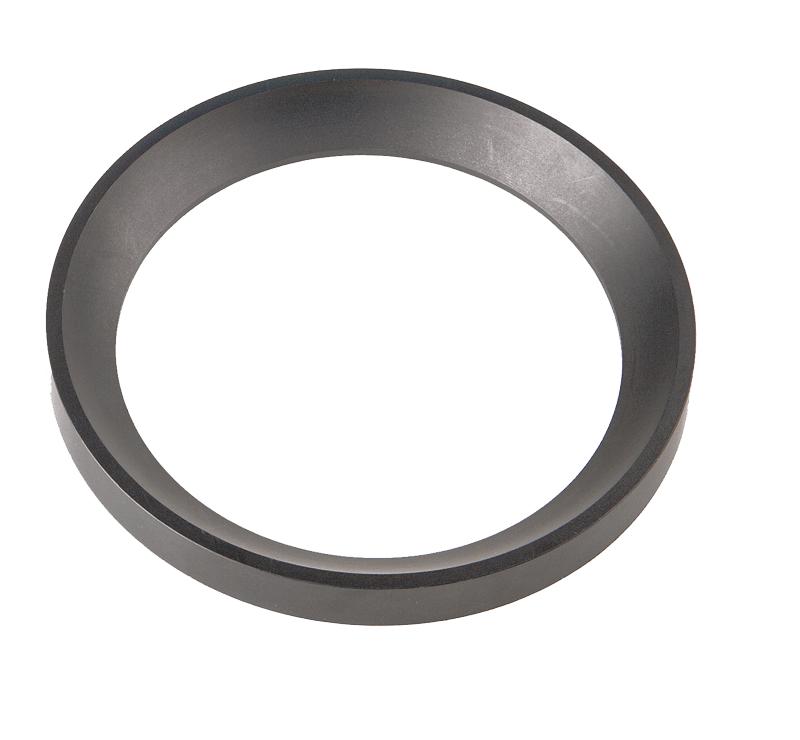

- Low friction shaft sleeves

- High or low temperature wear rings

- Thrust pads

- Diaphragms and membranes

- Valves

- Cryogenic valve seats

- Large chemical resistance valves

- Low permeability valves

- Seals

- Standard seals

- Spring energized seals

- Low permeability seals

- Expansion joints or bellows

- Corrosion liners

- Liners for expansion joint or compensators

- Bondable liners for tanks

- Anti-corrosion liners for power industries and fixing parts

3P: solutions complying with FHS standards

For oil & gas pumps especially, solutions provided by 3P are also listed in the API 610 11th edition. API 610 is a pump standard for centrifugal pumps in the petroleum, petrochemical, and natural gas industries, put forward by API, American Petroleum Institute, an organization that develops technical standards for oil and natural gas industries. Such standard are references for all activity worldwide.