PTFE lined vessels and tanks

PTFE is one the best corrosion resistant material available. As such, it is often used in the chemical industry to protect tanks and vessels from corrosion.

High protective barriers against corrosive chemicals

Our products are used for their high technical performance such as their chemical inertia to almost any liquid, a long lifetime, extended temperature range and good resistance to stress cracking.

3P-FluoLiner® range is particularly suitable for critical environments and used as an anticorrosion lining for high purity tanks, ISO containers, vessels or columns. They are widely applied to semiconductor, biomedical, pharmaceutical and fine chemical industries.

PTFE and fluoropolymer liner properties

3P-FluoLiner® sheets show high performances under a wide range of temperatures and pressures thanks to the best available heat and chemical resistance properties of fluoropolymers :

Outstanding resistance to a wide range of chemicals

- High purity

- Broad service temperature range

- Resistance to deformation and stress cracking

- No embrittling, no aging

- Hydrophobic

- Good anti-adhesion properties

- Lower maintenance costs

3P-Fluoliner are available with the following materials :

PTFE, the standard competitive solution

Modified PTFE, offering stronger mechanical resistance and lower permeability compared to PTFE. It also offers easier welding

PFA, is used for its god welding properties, making it fast to bond to tanks and vessels. It is also preferred in applications requiring high purity.

FEP, more competitive than PFA, used for lower temperature applications.

Etched and fabric backing

Etching

Etching is a chemical treatment by sodium ammonia on one side of the sheet, leaving a typical brown color. This side can be directly pasted, generally with acrylic or silicon paste.

Etching is available only on PTFE and Modified PTFE.

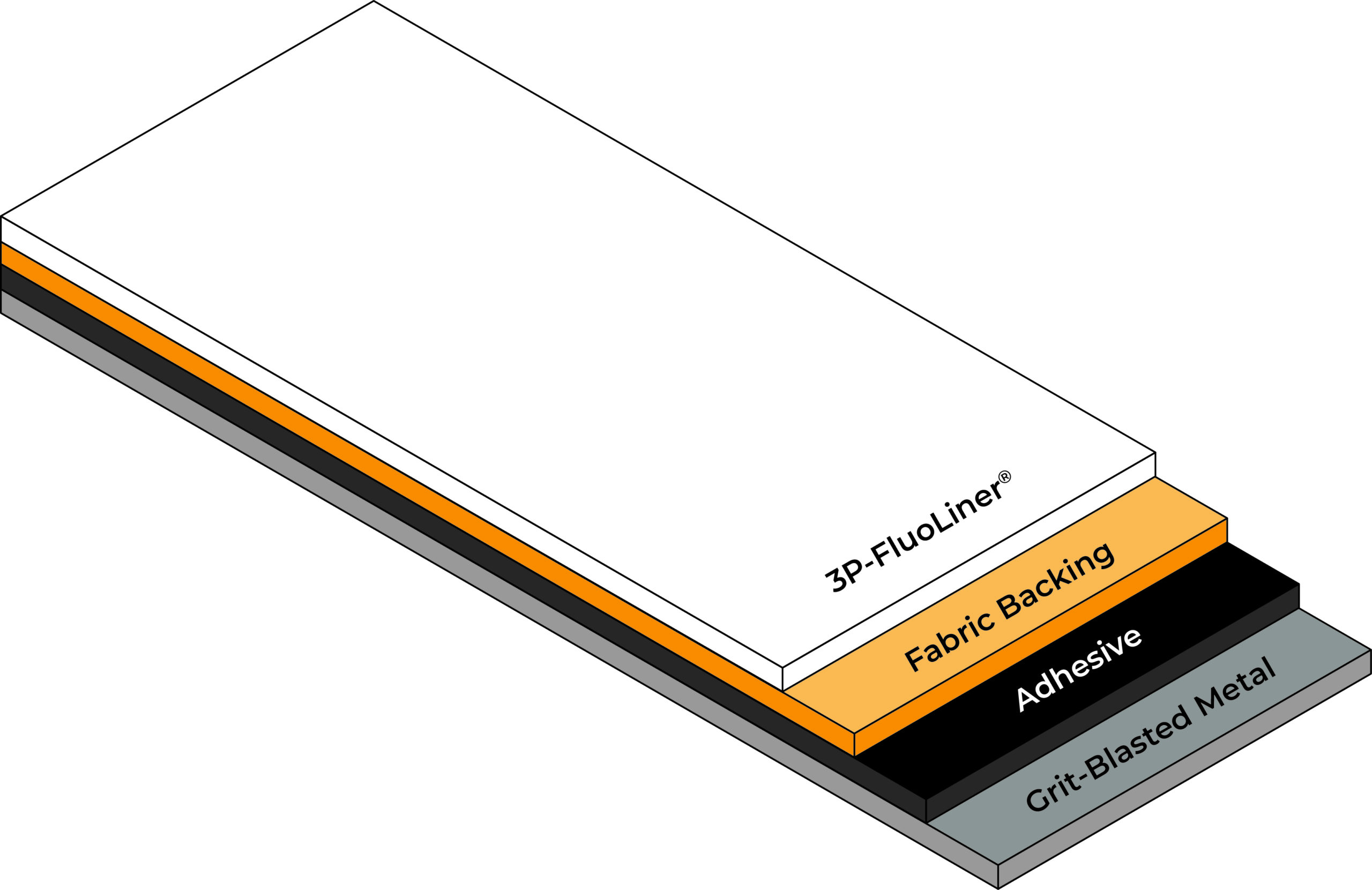

Fabric Backing

3P-FluoLiner® sheets can be laminated on a fabric backing. This process, more expensive than etching, allows a higher strength bonding to a wide range of substrates.

Fabric can be Carbon but more commonly Glass backing.

Fabric backing is available on all fluoropolymers.

Comparison of bonding performance between etching and fabric backing

The main difference between Etching and Fabric Backing is the bonding strength, higher for Fabric Backing.

Sheet lining range

Welding rods in FEP and PFA and cap strips in PFA are also available.