PTFE tubes are a versatile solution for the industry.

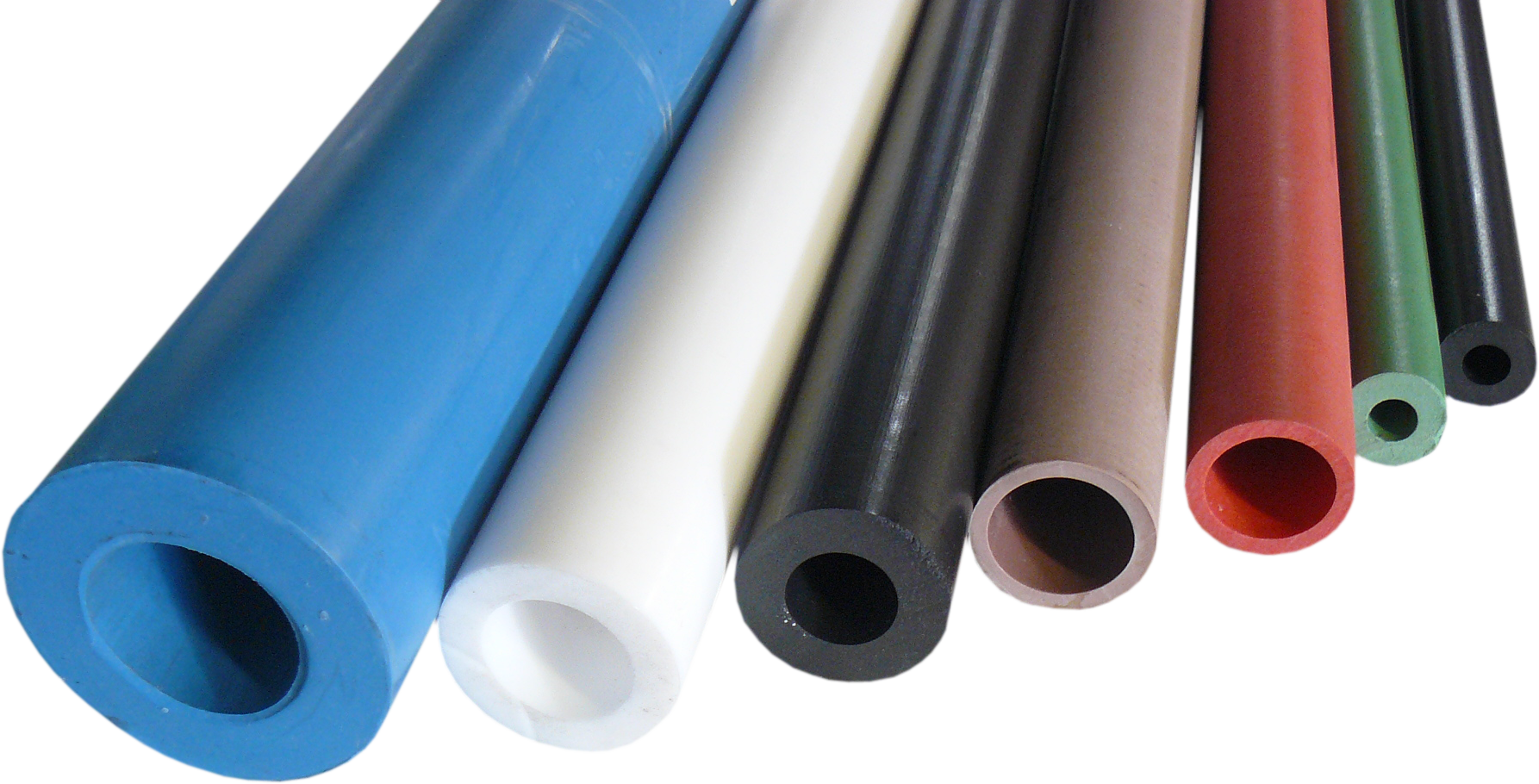

When referring to PTFE tubes, a lot of applications come to mind. As well as a lot of shapes, PTFE tubes include different families, from molded tubes to extruded tubes. Extruded tubes, also known as thin wall tubes (TWT) can also be convoluted or partially convoluted.

Choosing extruded or molded PTFE tube?

Therefore, 3 main processes allow to produce tube-shaped PTFE parts:

All the assets of PTFE in one product

PTFE tubes are very versatile because all the characteristics of PTFE are preserved. Most properties offered are:

- Dielectric insulation

- High flex life

- Low friction tube

- High temperature resistance, up to 260°C

- Anti-corrosion protection

- Inert

- Non- toxic, with FDA grades for food and beverage handling or medical grades

- Low friction tube

- High temperature resistance, up to 260°CNon-flammability

- Natural UV-resistance and high resistance to outdoor exposure

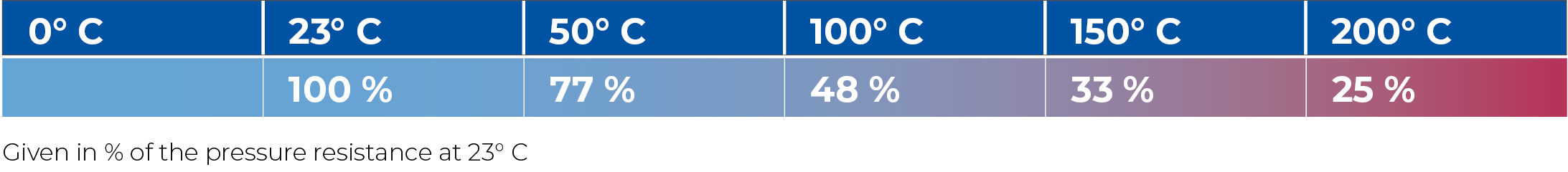

- Plus its high temperature is an important asset, as it can withstand strong pressures. At 200°C, the burst pressure is still 25% of the burst pressure at room temperature. Not all thermoplastic can provide such a performance !

Typical uses

Thanks to all of its properties, PTFE tubes have many application’s.

One popular application is the use in 3D printers as its low friction makes it a good filament guide.

In demanding industries, they are the main component of hoses, like smooth tubes or corrugated ones. Typical uses include the food equipment industry and even housewares. They are safely used in contact drinking water. Or on the contrary, PTFE tubes are one the best solutions to transport corrosive fluids like acids.

They are also commonly used in transportation (in aeronautics or automotive, as well as trucks, railway or bikes), as they can transfer fuel, oil or other corrosive fluids like brake fluids.

They also are often used as liners. A common application is the use as control cable liners. Thanks to low friction, a PTFE liner allows for high efficiency. The use of specific compounds can also increase the resistance of PTFE to wear and significantly increase the lifetime of control cable systems.

Finally, PTFE tubes are commonly used to protect electric cables from their environment or from friction, or to increase insulation.