High performance plastics parts answers the needs of energy industry

Energy & sustainable development industry are facing new challenges every day. Systems are rapidly evolving and still meet efficiency and safety constraints. Answering these key factors typically require high performance plastics, mainly PTFE and PEEK.

Assets of PTFE and PEEK for energy industry

Energy is core for developing both productive and sustainable activity, as much for industrial as for personal ones. The energy industry is facing both challenges for cleaner energy and for an increase in efficiency, as the demand for electricity continuously rises.

New ways to produce, transport and store electricity are constantly being tested and validated. During all these steps, systems must be protected from harsh environments, see their efficiency increase, their lifetime expand and their cost decrease.

Solutions based on fluoroplastics are therefore common in such industrial energy sector.

High electrical insulation or data protection through components with high dielectric load are typical applications where the right design can provide long-standing assets.

The development of offshore industry increases the maintenance constraints in harsh marine environments.

Lots of solutions are based on fluoropolymers and high performance plastics. PEEK and PTFE mainly prove themselves mandatory to overcome all the challenges in one simple, competitive solution.

Such solutions show optimal properties, such as

- High temperature performance

- Ultra low inflammability

- UV-resistance

- High electric insulation

3P: High Performance Products Complying with Energy Standards

To ensure the very high quality and reliability that these markets require, 3P is ISO 9001 compliant, among other qualifications.

3P is also committed in respecting environment and is ISO 14001 certified.

3P offers reliability for energy industry

Critical applications where 3P is sought are for example medium or high voltages. Based on special compound, solutions adjusted by 3P are trusted for the reliability of a whole electric distribution system.

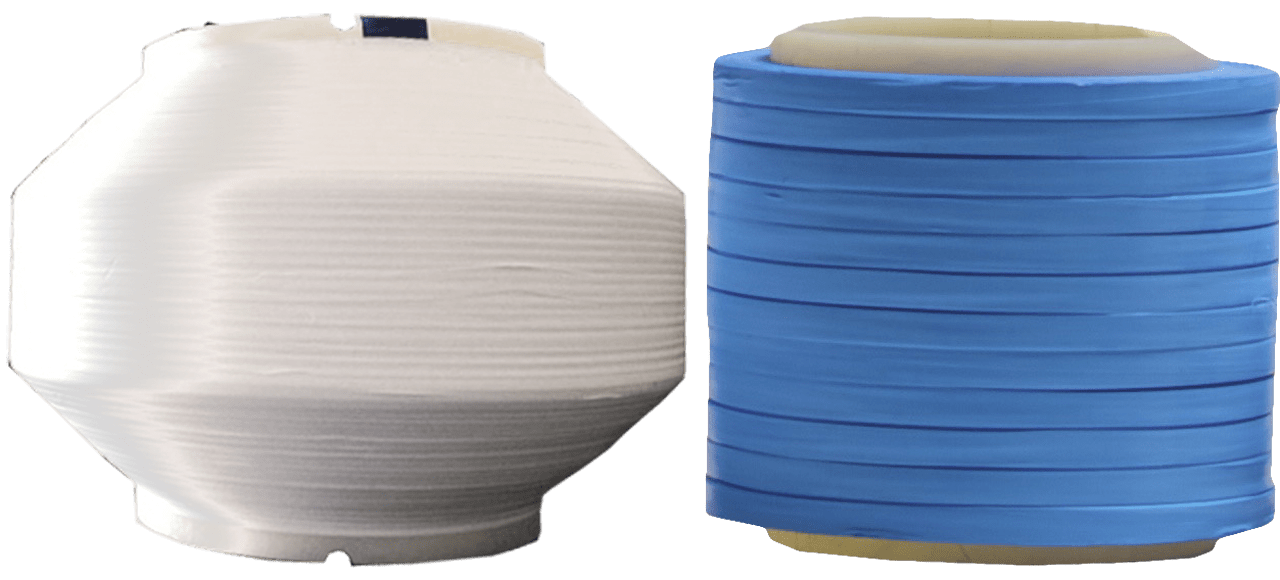

Moreover, 3P is a world leader in PTFE tape, which can be found in electrical or data cables. Heating cables are also an important share of PTFE applications.

Cables based on wrapped PTFE tapes are recommended when applications demand high flexibility. Chemical resistance and temperature are also seeked properties. Also wrapped tapes offer low thickness unavailable with other processes, which allow full miniaturization of the cables.

The high expertise of 3P in such cables explains its position as world leader for cable suppliers. The strict control of low thickness tapes is also a strong asset offered by 3P for data cable. Such data cable require low-density, which are much more challenging. And low-density PTFE tapes are used in the most demanding microwaves/high frequency data cables, protecting the signal integrity.

Finally, the production of PTFE tapes in Europe and USA is a proof of our capacity to support our customers in their worldwide activity.

3P solutions can be found in many applications for cable and harness manufacturers or grid equipments:

- Cable manufacturers

- insulation tapes for cable wrapping

- jacketing unsintered tape

- Low-density PTFE tapes

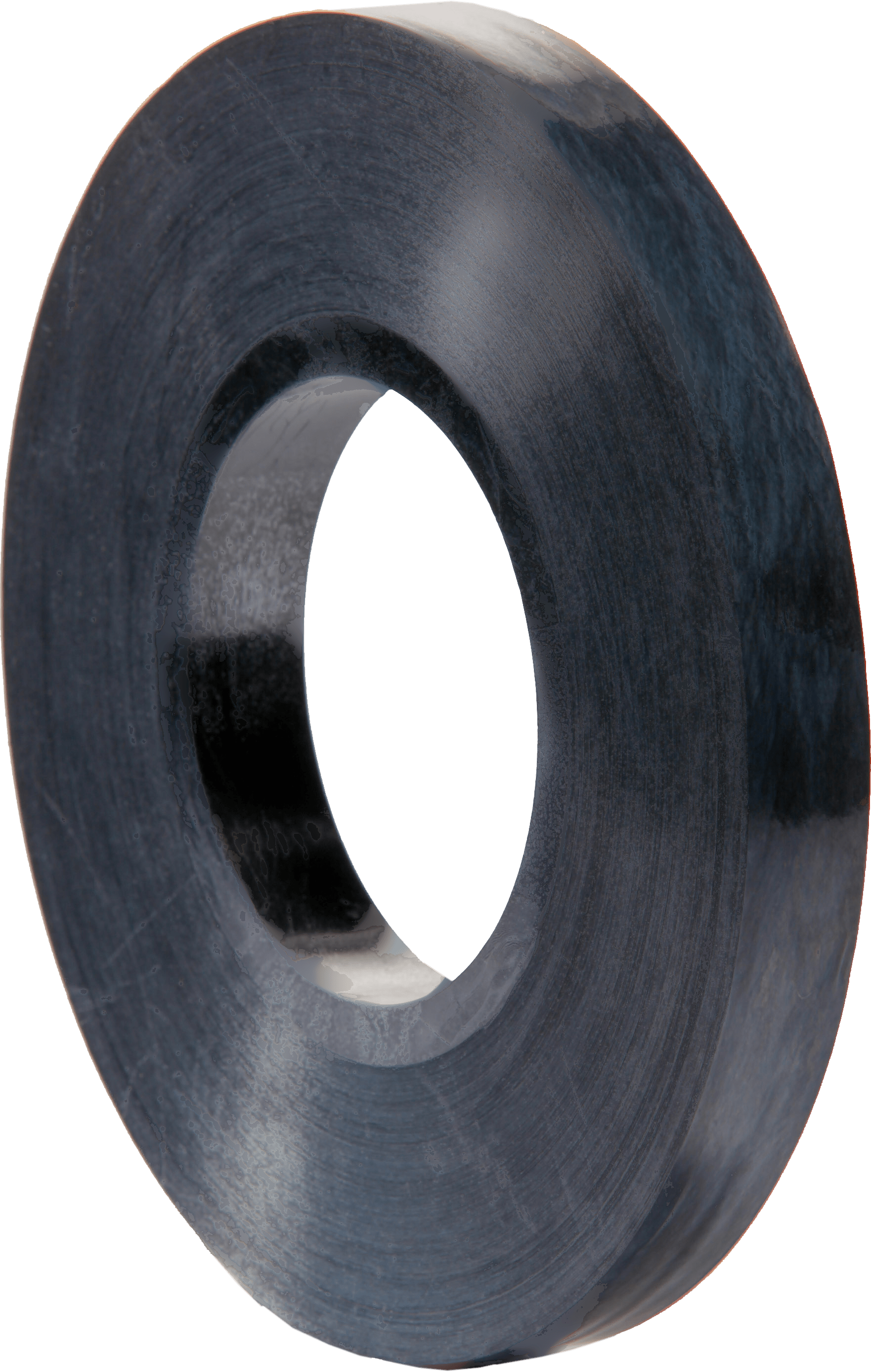

- Semi-conductive tape

- Skived tape

- Fillers and cord

- Harness

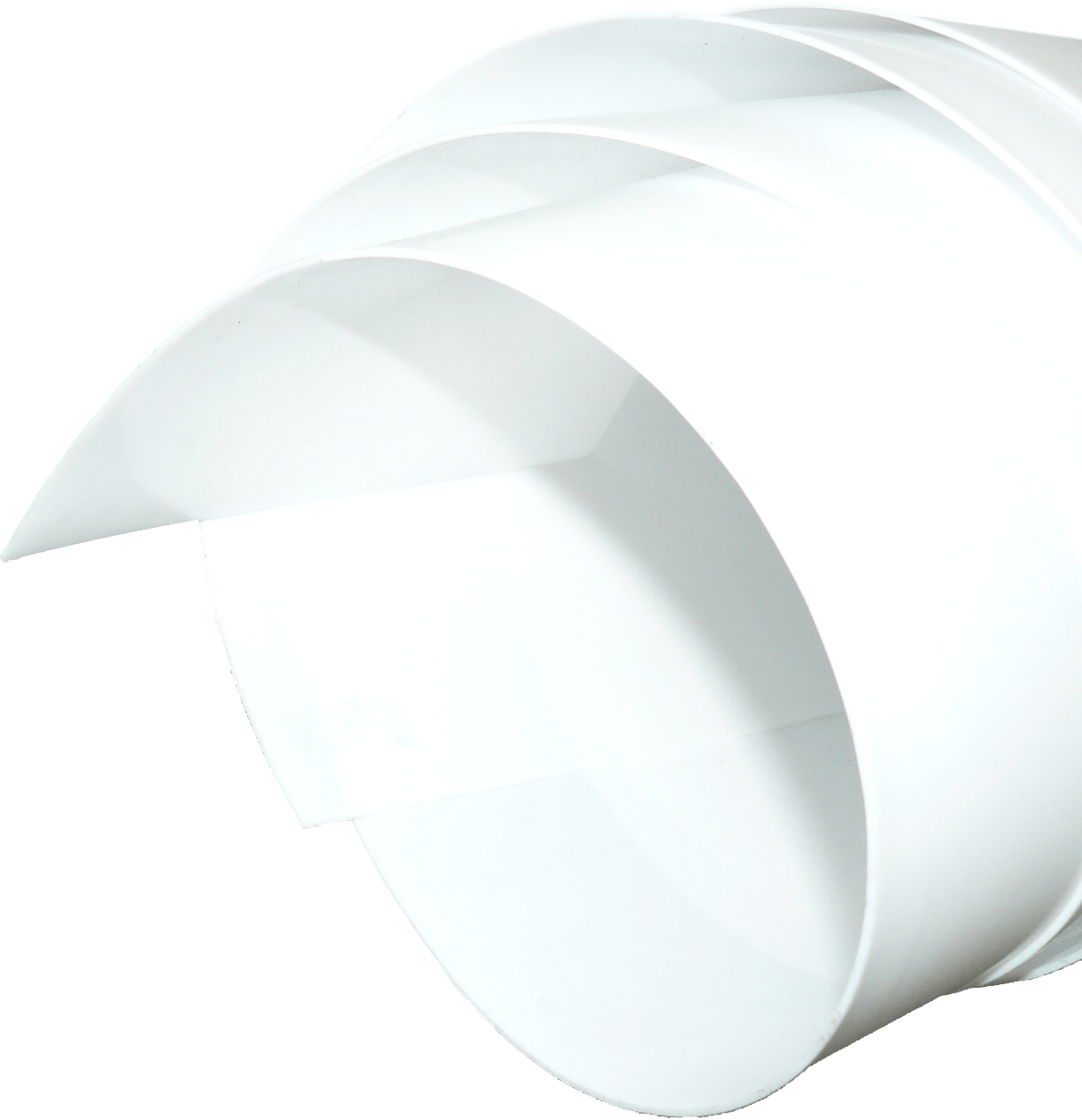

- Convoluted tubes for cable protection

- Skived tape for cable protection

- Connectors

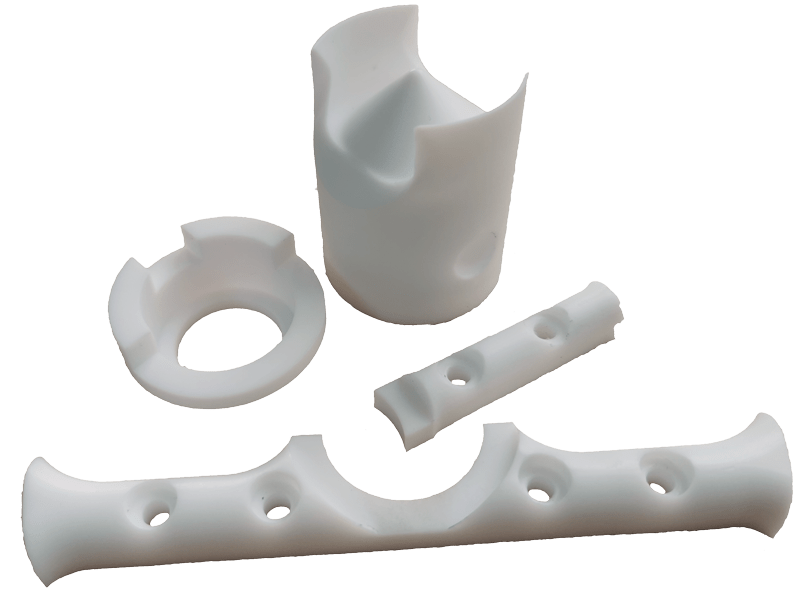

- Fastening systems (clamp block, bobbins, coil holding…)

- Medium or High-voltage equipment

- Nozzles for circuit breakers

- Insulated casing

- Guiding ring

- Protective band