PTFE venting membrane

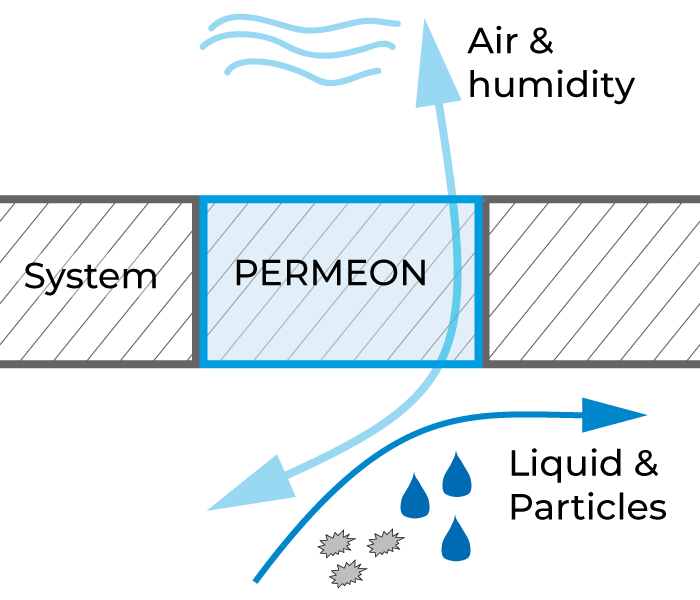

Venting or breathing membranes are required to protect an enclosed area from condensation and humidity. Gas and humidity can go through PTFE vents while dust and water are blocked. PTFE vents maintain pressure equilibrium and avoid fissurations of the packaging.

Solution to protect electronic from temperature variations

Critical and fragile components like electronics are kept in a closed environment. When the system works, the environment is often exposed to temperature variations. Due to temperature variations, humidity and condensation can appear and deteriorate the components.

If the environment is clean, a simple hole will be enough to equilibrate pressure and humidity. But if you want to protect your fragile component from dust and water, you will PTFE venting.

Breathing membranes and venting membranes are the best solution to allow humidity and pressure equilibrium between inner and outer space, while preventing contamination by dust or liquid. And PTFE breathing material are acknowledged as the most versatile solution for this application.

Permeon® is a unique resistant PTFE vent

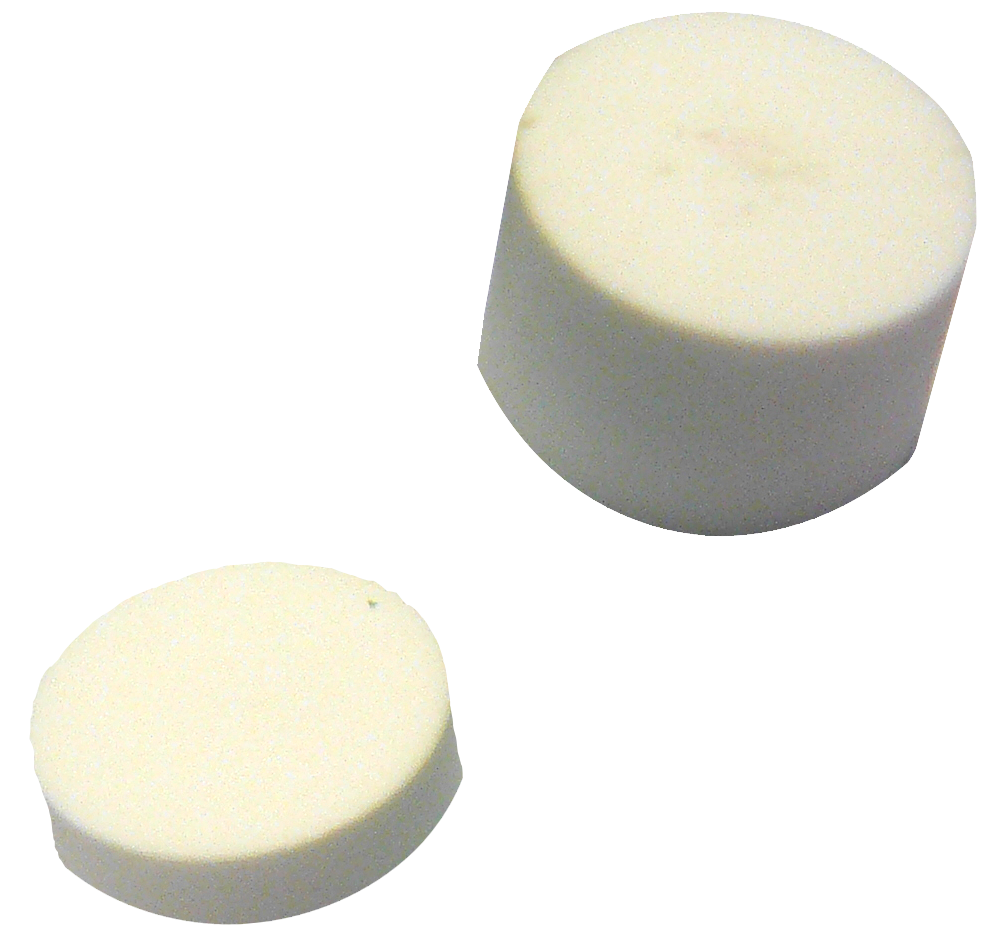

Permeon® is a 100% PTFE venting solution, showing high thermal and chemical stability.

It is based on sintered porous PTFE.

Compared to stretched ePTFE, it offers:

- high mechanical properties: resistance to high pressure projection (Kärcher test), no need for plastic cap (that induce low venting surface)

- high temperature resistance: no soldering, no adhesive needed

Permeon® adapts to your system design

Machined parts are custom designed to fit any system. Seamless pastilles are no constraints for the design of the whole system.

This unique design allows :

- plug-in assembly: no support or cap, simple assembly, simple system preparation for global cost gains

- seamless integration: no space required around the assembly

3P develop the venting performance for your need

Each solution is developed for the real conditions.