High performance automotive plastic part for critical components

Automotive industry sustains strong evolutions. Vehicle electrification and imperatives of efficiency are the most impacting. To answer these challenges, PTFE and high performance materials are often the best solution.

Materials follow the evolution of the automotive market

Automotive equipments may need improvements of subsystem or even full redesigning to meet these new trends. High performance plastics and composites allow to answer new designs, where engineering plastics or even metal fail.

There are lots of examples. The use of high performance thermoplastics like peek, or peek-based composites allow metal substitution in critical parts, and lighter, more efficient systems.

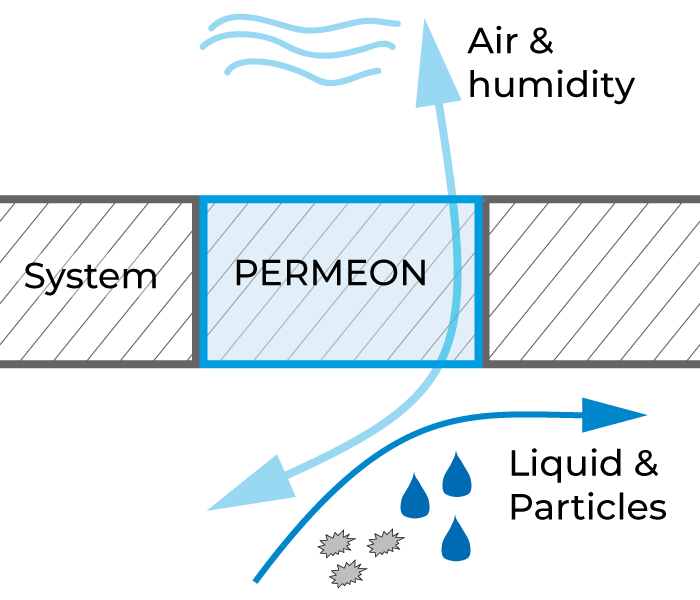

Protection of electronics require PTFE venting membrane. They protect electronic equipments from humidity and dust.

Tribology and control of insulation are also important for electric motor, and an efficient traction. There, lip seals offer the best combination between sealing and friction. And they are available as conductive or semi-conductive materials.

In all these applications and in numerous other solutions, PTFE, fluoropolymers and high performance products have proven their superiority and are unrivales.

3P offers new performance for automotive industry

Automotive equipments may need improvements of subsystem or even full redesigning to meet these new trends. High performance plastics and composites allow to answer new designs, where engineering plastics or even metal fail.

Automotive equipments may need improvements of subsystem or even full redesigning to meet these new trends. High performance plastics and composites allow to answer new designs, where engineering plastics or even metal fail.

Trusted by the world automotive biggest companies, we have developed an outstanding expertise in helping automakers and Tier-1 suppliers to find the right solutions. Our know-how enables us to offer innovative and customized solutions to critical applications.

Our products show optimal properties, such as:

- Extremely low coefficient of friction.

- Remarkable longevity.

- High capacity to withstand extreme temperatures

- Excellent thermal stability

- Exceptional chemical resistance

- Good dimensional properties

3P co-develops performance solution for automotive industry

With our proven track record, you can find 3P’s products in nearly any automotive equipment, from steering to transmissions, or even fuel tanks.

Below are examples of constraints we answer in different systems

- Sealing application (shock absorber… )

- Virgin and Filled PTFE Seals, etched or not.

- Crankshaft Seals

- Valve Rod Seals

- Piston Seals/Slip Joints, Valve Rings

- Overmolded and Thermoformed Pistons

- Valve seat

- Back-up ring

- O-ring, segments, washers

- Friction and wear

- Control cable liners (gearbox commands, Cables of Release Mechanisms for the Hood and Trunk; Door and Window Handles, Side Mirrors and Fuel Flaps, HVAC control)

- Injected parts and assemblies (ball joint cage, ball bearing cage…)

- Clutch Fork Bearings

- High precision injection of gears

- Slide rings

- Breathing applications

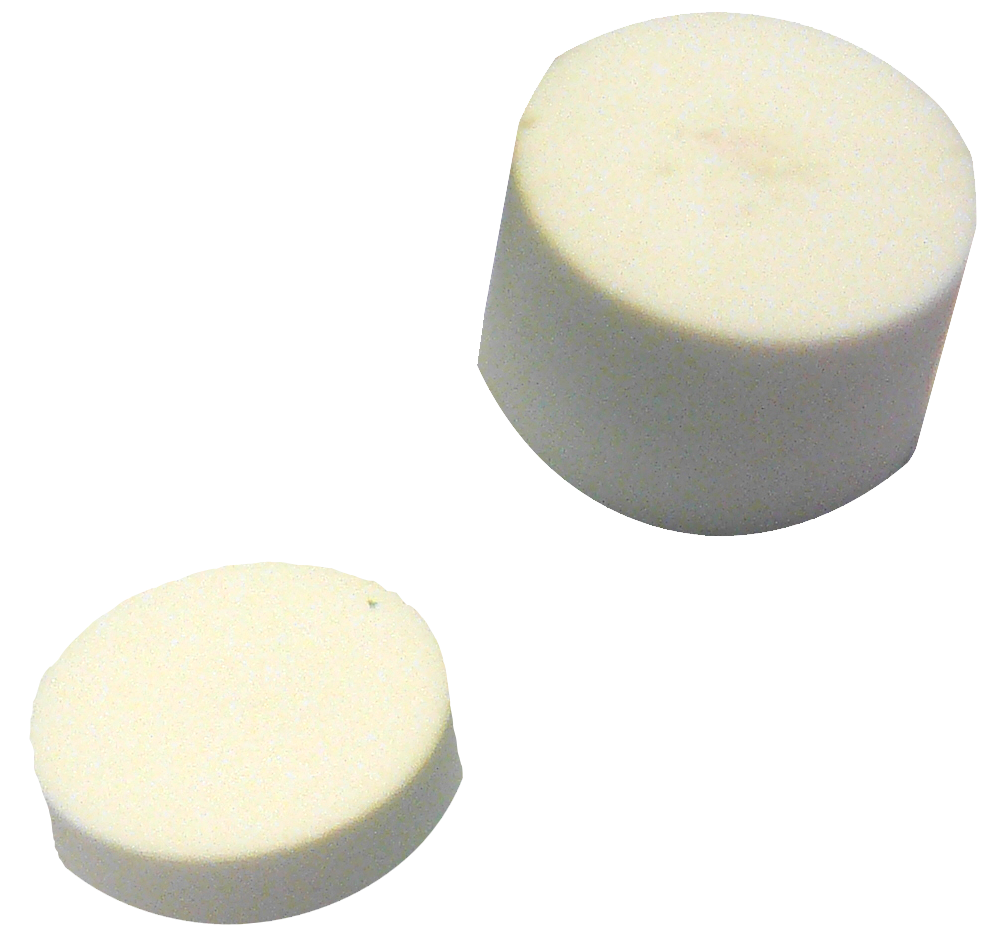

- PERMEON® pastilles for venting

- Liquid/gas separators

3P: High Performance Products Complying with automotive Standards

To ensure our products meet this specific market standards, 3P has obtained the IATF 16949 global certification, replacing ISO/TS 16949.

3P is also committed in respecting environment and is ISO 14001 certified.