Etching allows PTFE bonding

PTFE is naturally non-adhesive. If you need to bond to another surface, metal, plastic or rubber, etching is the only way. Etching consists in modifying the PTFE surface so that adhesives will stick on the surface.

Surface treatment of PTFE to ensure a lasting adhesion

Etching consists in treating the surface of PTFE parts to lightly modify its chemical structure on a thin material layer. As PTFE is one the most corrosion resistant material, only a few solutions are available for this. This also explains why the modification of PTFE will only apply on a thin layer and will not deteriorate its sealing or chemical resistance on the rest of the PTFE part.

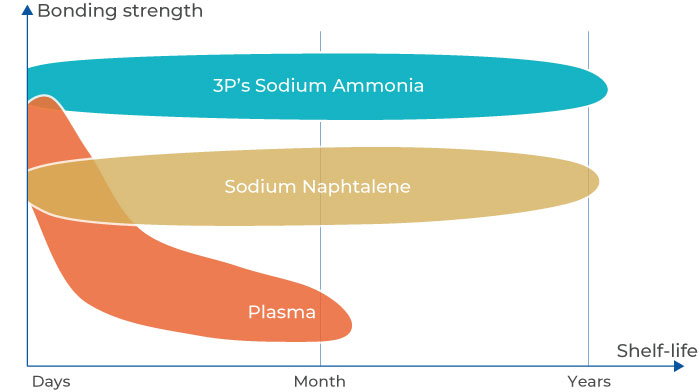

3P uses the sodium ammonia etching process, which is the most effective and longer-lasting way of etching. Etching is applied on all kinds of parts: films, PTFE adhesive tapes, but also on cut or machined parts.

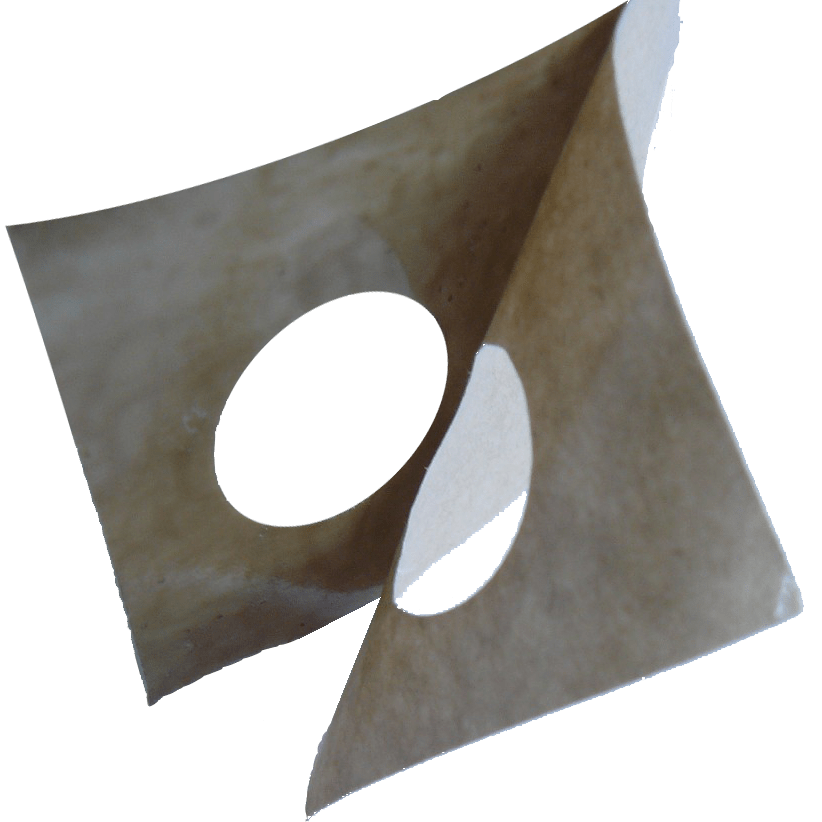

Etched parts can easily be recognized as they show a typical brown coloration.

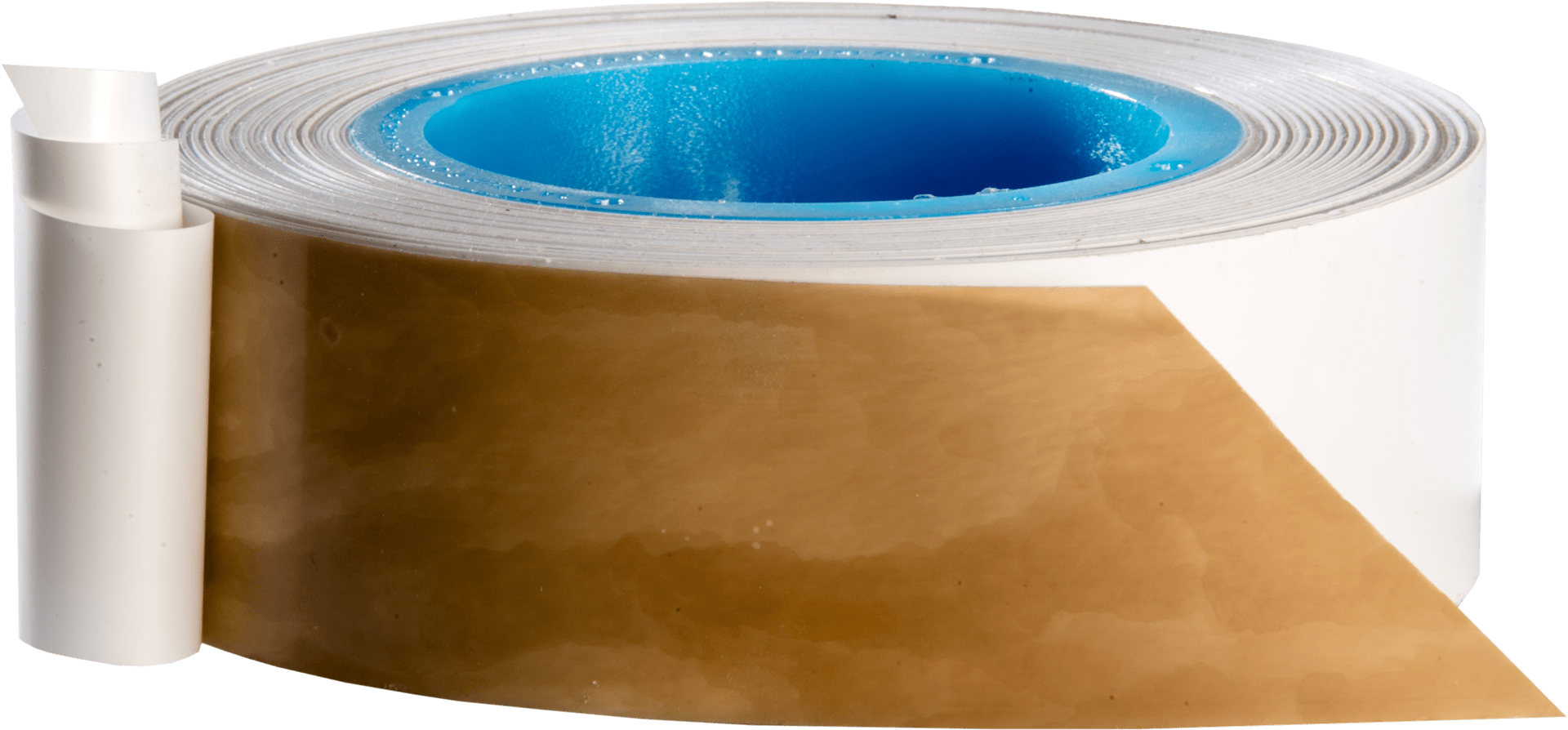

Adhesive PTFE with silicon or acrylic

Semi-finished or finished parts are supplied with etched surface. They are also available with the adhesive.

With a fully integrated process, including etching and adhesive, 3P offers high stability adhesive tapes and films.

3P also integrates cutting processes to the required drawing, for easy integration.

Silicone and acrylic are the preferred adhesives. Still other options are available. The adhesive must be selected for its compatibility with both surface material and service temperature.

Acrylic adhesive supports higher strength (20 N/25 mm for tapes) and can be used from -55°C to 85°C.

Silicone supports 7 N/25 mm (for tapes) and can be used on a wider temperature range, from -85°C to 150°C.

3P is one of the main suppliers of etched or adhesive PTFE films for aeropace industry. Therefore, they can be provided according to custom requirements or according to ASNA 3634 or ABS 5766 requirements respectively.

3P also offers the 3P-FluoLiner® range of etched PTFE sheets. These sheets are mainly used as a protective anticorrosion liner for high purity tanks, ISO containers, vessels or columns. Our products are used for their strong adhesive capacity on steel substrates, their chemical inertia to almost any liquid, a long lifetime, extended temperature range and good resistance to stress cracking.

PTFE assembly

As more and more industrial companies request complete ranges of solutions, it is also possible to outsource the bonding and the assembly.

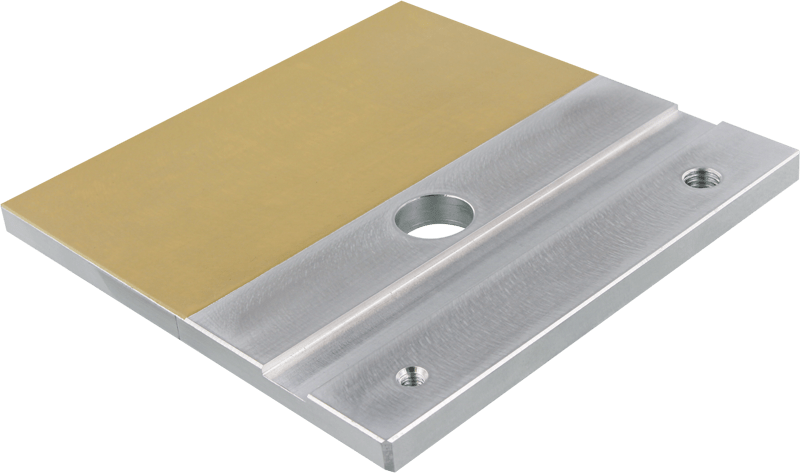

3P has recently investing in curing equipment to bond PTFE to metallic surfaces. This process is compatible with a drastic control of impurities. This ensures a trusted bonding of PTFE on metal parts.