Our Key Features

Choosing 3P for your projects is the guarantee of the best expertise in all kind of high performance plastics and processes, a foolproof performance and a certified quality dedicated to your specific needs.

50 years of experience

In satisfying the most demanding markets by designing, developing and manufacturing creative products and solutions.

A team of more than 20 Experts

Fully dedicated to the development of innovating solutions to answer your current challenges and anticipate the future ones.

8 Companies across 3 continents

To always be close to you, because we know that proximity plays a great part in understanding our customers’ needs.

A large range of solutions

The right solution is always within your grasp thanks to our large materials range and transformation processes.

The quality Certifications of the most Demanding Markets

According with their markets, our facilities are certified ISO 9001, ISO 14001 but also EN/AS 9100 and IATF 16949.

A renownedPerformance

3P has been recognized as one of the best French businesses because of its exceptionnal performance.

Get the Expertise of the Most Challenging Markets

Aerospace

3P develops products with unique advantages for the aerospace industry: from fire and arc cracking proof PTFE unsintered tapes to lightweight and anti-corrosion thin wall tubing, molded parts and small assemblies…

Automotive

With a long track record in automotive industry as Tier 1 and Tier 2 supplier, 3P’s solutions contribute to any driver’s comfort through increased reliability and efficiency.

Oil&Gas, Chemicals and Fluid Handling Systems

For all kind of Fluid Handling Systems, 3P designs its own compounds to improve longevity and efficiency. 3P’s products are especially assessed in pumps and valves for the petrochemical industry.

Energy & Sustainable Development

Whether standard or customized, our products for the electrical and renewable energy and for the sustainable development provide our customers with insulating parts in compliance with their specific needs.

General Industry

Thanks to our capacity for technical design and industrialization and our technical knowledge of polymers, we are able to offer specific solutions for a vast number of industrial issues.

Industrial Distribution

3P has been supporting distribution for almost 50 years by manufacturing cleaner, lighter, and longer lasting components for all kinds of applications (electrical, mechanical, sealing applications, etc.).

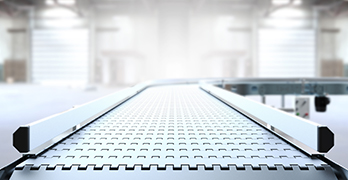

Discover our Product Ranges

Our industrial capability and our proficient know-how make us able to produce a wide range of products, from basic shapes to very complex parts. Because we only use high-performance plastic materials, our products answer outstanding characteristics: resistance under extreme temperatures, resistance under fire exposure or exposure to extreme environmental conditions, resistance under high mechanical stress, a very low friction rate, a very high insulation rate, and more. Our ranges – from classic to premium – enable you to choose the best solution both in economical and technical terms.

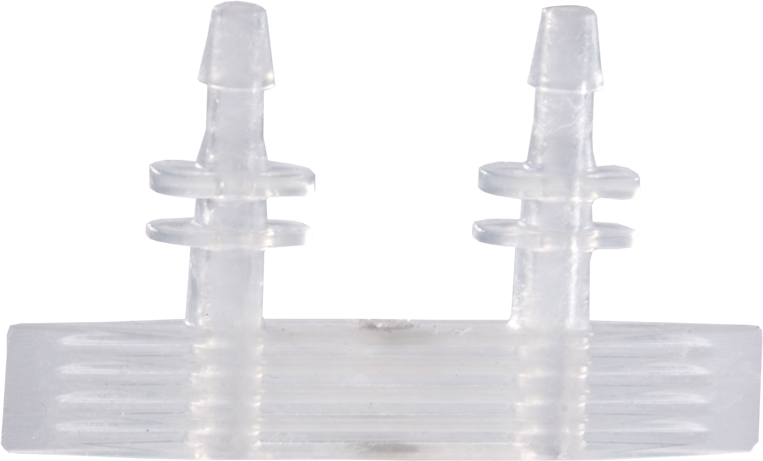

Tubing

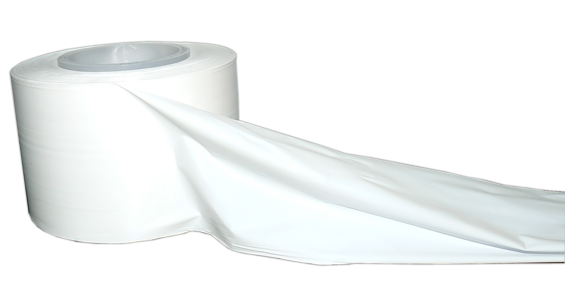

Films & Tapes

Skived Tapes & Liners

3P Solutions

Molding

Discover our Product Ranges

Our industrial capability and our proficient know-how make us able to produce a wide range of products, from basic shapes to very complex parts. Because we only use high-performance plastic materials, our products answer outstanding characteristics: resistance under extreme temperatures, resistance under fire exposure or exposure to extreme environmental conditions, resistance under high mechanical stress, a very low friction rate, a very high insulation rate, and more. Our ranges – from classic to premium – enable you to choose the best solution both in economical and technical terms.

Tubing

Films & Tapes

Skived Tapes & Liners

3P Solutions

Molding

Our Materials

PTFE is certainly the most common fluoropolymer, and the first high performance polymer. Thanks to its chemical structure, it features one of the best available chemical resistance of solid materials, and the best resistance amongst plastic. It is also recommended for its high insulation properties and its low friction behavior, amongst other outstanding properties.

While it is a thermoplastic, PTFE is too viscous when melted and can’t be processed with the usual methods. Especially, PTFE can’t be injected, complex parts are produced by molding and machining.

A large range of PTFE compounds and composites is also available to improve performance in specific uses, mainly to improve its mechanical performance.

PTFE is also supplied as tubes (with large or thin tube walls), rods, films (sintered or unsintered), tapes, liners or molded basic shapes (sheets, rods, dimpled sheets)

PFA is a fluoropolymer with performances close to the ones of PTFE. As such, it offers good mechanical properties at high temperatures. The main advantage of PFA is its high purity combined with a larger transformation panel: PFA can be injected or directly extruded, and thus offer a large range of complex parts with a competitive process.

PFA is also available in compounds offering increased stiffness or strength. This allows the use of its high chemical resistance, one of the highest available, in demanding mechanical applications.

Virgin PFA is certainly the preferred material when facing high purity challenges. It is therefore often used in chemical production or in semi-conductor industry. FDA and WRAD grades are also available for food industry.

FEP is a fluoropolymer with a chemical structure close to the one of PTFE, with only carbon-fluorine bonds. Thus it matches PTFE’s outstanding chemical resistance. It can be used in environments up to 200°C (400 F).

This material can be injected or directly extruded. Competitive processes like injection or direct extrusion offset its higher gross price.

FEP is often preferred in applications with high transparency and with high volume requirements.

Just like most high performance materials, it can be used in food and beverage industries, as FDA or WRAS grades are available.

PCTFE is a fluoropolymer, whose chemical structure includes chlorine. It is recommended for applications in contact with cryogenic fluids, as it keeps strong mechanical properties even at -255°C (-427 F). It also has a low absorption level, even for gases. It is therefore a solution often considered in fluid handling systems or in the aerospace industry.

PCTFE is available as basic shapes (sheets, rods and tubes) and as machined parts with high precision for such demanding applications.

Moulded PCTFE parts are preferred to extruded ones for better mechanical properties.

PEEK is a thermoplastic polymer recommended for its high temperature resistance and its high dimensional stability. With its light weight, it can even replace some metal parts in harsh environments, where it offers improved efficiency.

Variants of PEEK can be found in its polymer family, the PAEK (polyaryletherketone), when custom properties are needed.

PEEK compounds are common in demanding industries to achieve the best performance available. If standard compounds don’t fulfill your needs, custom fillers can be developed for these specific applications. 3P a développé tout une gamme de compounds, mais aussi de composites, avec notamment des solutions propriétaires de composites en fibre continue.

PEEK can be injected, extruded or molded. It is available for complex parts, even for high precision injection. Molded or extruded parts are available, depending on the requested performance.

PI and PEI are part of the same large range of imide based polymers: polyimide and the variant known as polyetherimide. Such high performance polymers are preferred for their very high temperature resistance and thermal stability.

With good resistance to radiations, they are also used in nuclear application.

Welcome to the World of 3P

Sales Offices Factories & Sales Offices